Forced Draft Cooling Towers

Forced Draft Cooling Towers

The forced draft cooling towers represent a flexible and powerful but economical cooling technology suitable for the most of industrial plants.

We provide both design and construction of the forced draft cooling towers, as well as complex delivery of particular parts from our own production and from verified suppliers. The forced draft cooling tower designs are always created based on specific customer needs, and they comply with required parameters, local conditions, water quality, and other specific conditions at the installation site.

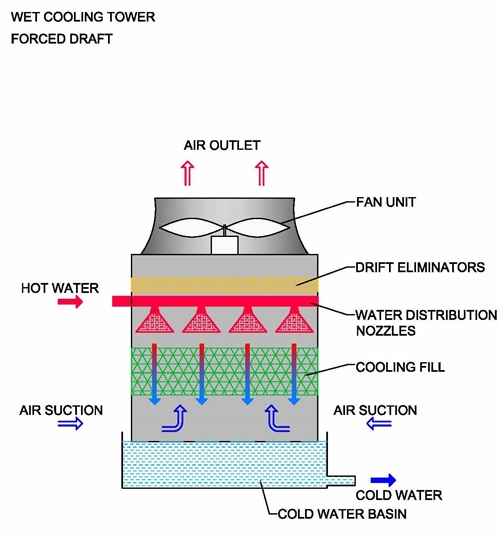

Components:

- outher shell (material: FRP, steel, stainless steel, concrete)

- supporting structure

- fan stack

- cooling fill

- drift eliminators

- fan with drive

- water distribution system including sprying nozzles

- water basin

The forced draft cooling towers remove low-potential heat generated in the production process. They use atmospheric cooling with wet technology and forced draft. A counterflow of air and hot water in the cooling fill results in a heat transfer. The air flow is provided by a propeller fan while the drift eliminators prevent the transfer of small the tower space.

Industrial application:

- energy industries

- petrochemical industry

- chemical industry

- engineering industry and metallurgy

- mining industry

- plastic and rubber industry

- paper industry

- manufacturing industry (food-processing, sugar refineries)

Potential optimization:

- used materials and components

- total cooling efficiency

- operation and maintenance economy

- noise elimination

- reduction of environmental impact (water and energy savings)

- ATEX design for explosion hazard spaces